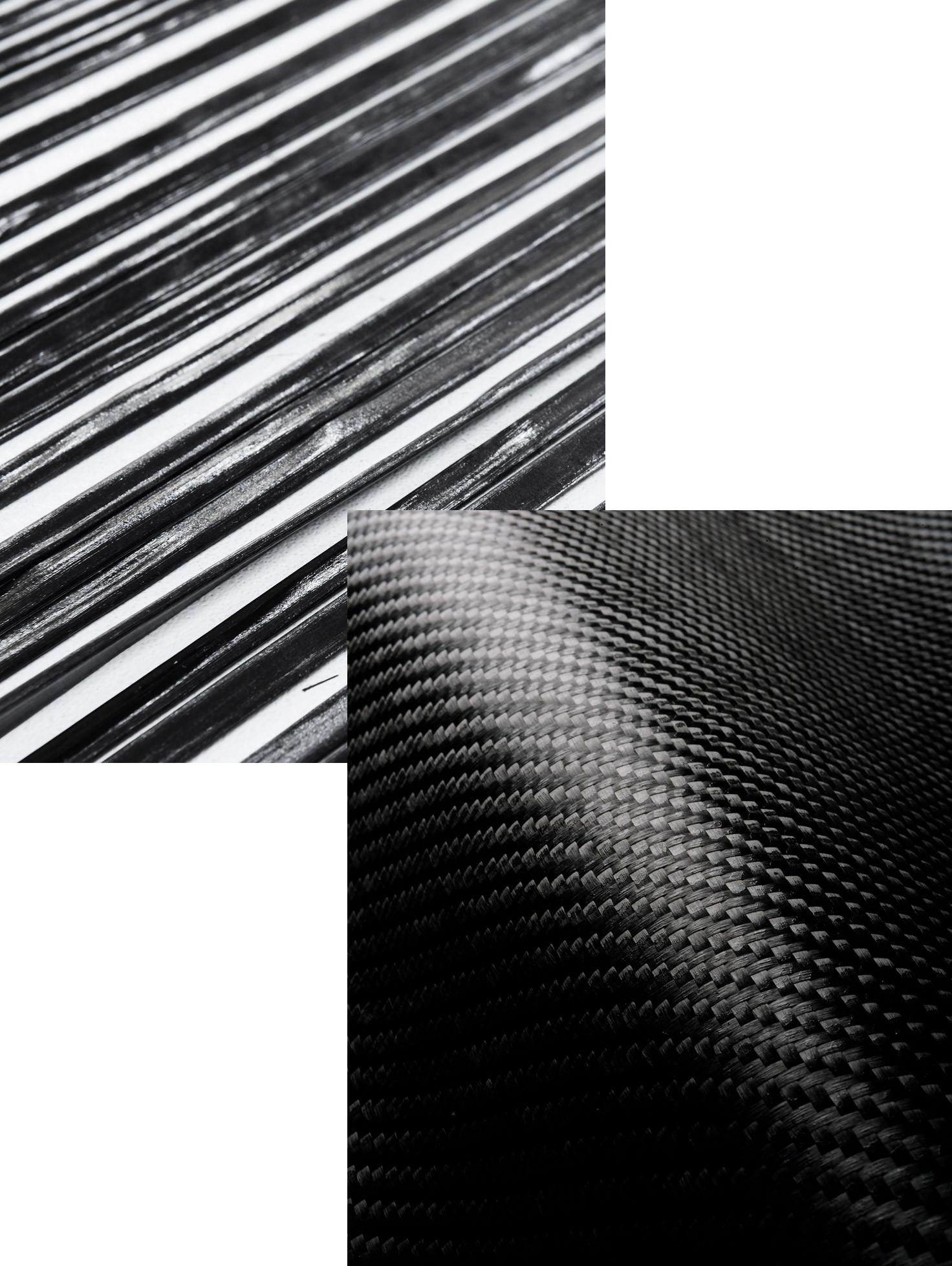

CARBON CORE

OUR DNA IS CARBON

Thirty years ago, LOOK began an extraordinary adventure of manufacturing carbon frames and forks.

Thirty years ago, a time when steel frames tamed the hig hest peaks, LOOK took up the incredible challenge of mastering a new material, carbon. The carbon we are discussing today is nothing other than a high-performance fiber with incredible mechanical properties that require great expertise in its transformation process. Used in fabric form and in layers pre-saturated with resin, it is possible for us to manufacture lightweight and complex parts of unrivaled performance to date in the world of cycling.

What seemed to be a fantasy thirty years ago, has turned into true acquired know-how that has become the pride of an entire company. Day after day, month after month, our passion grew more and more, finally leading to the creation of our company culture, our DNA.

"Something to be proud of, the architects of the victories of champions."

HANDMADE

Global successes belong not only to the champions, but also to all those in Nevers who, every day, continue to innovate, constantly improving the know-how, working to the highest precision, controlling everything to the finest detail in each production step, torturing every material, eliminating everything that has the slightest defect and continuing, today as yesterday, to manufacture and assemble each fork and each frame by hand for the enjoyment of all those who love cycling.

A UNIQUE KNOW-HOW

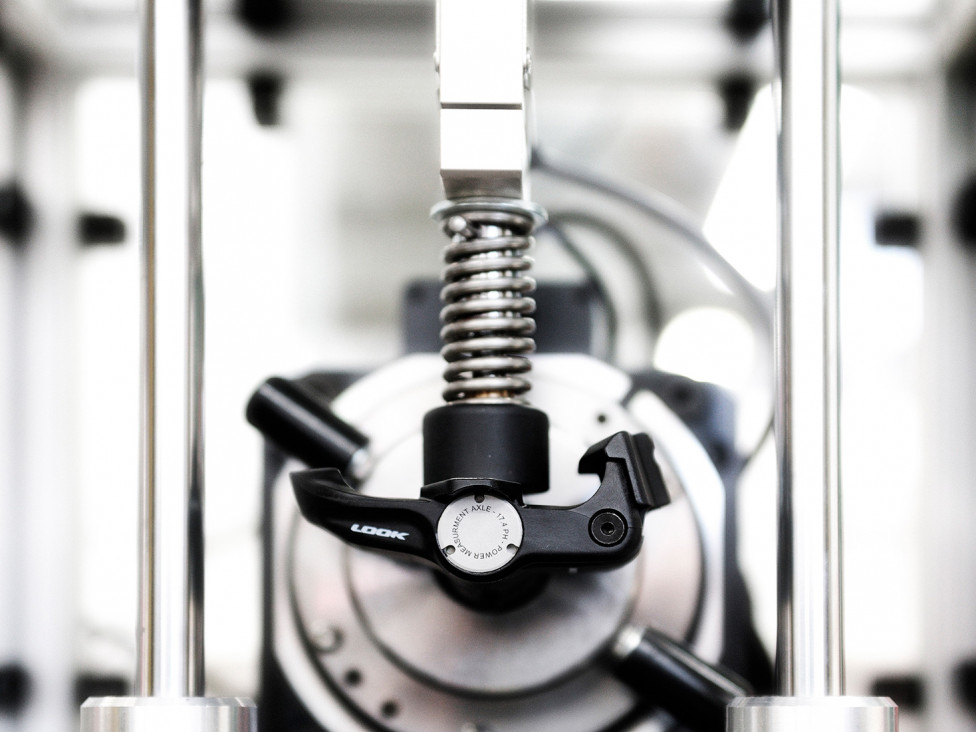

For over 30 years LOOK has developed in its own factories a unique expertise and a vast know-how in the carbon field to reach specific desired properties. Once the optimal shapes had been created, our engineers work on the processes and on the carbon for each area of the pedal in a very precise manner in order to achieve our goal : the creation of ultimate aerodynamic and light pedal.

Cutting, Assembling and Molding

STEP 1

The carbon material provides elasticity, flexibility, liveliness, performance, responsiveness and comfort. Qualities that no other material possesses that allows frames to maintain their initial geometry all their life. As for resistance, it is 5 times superior to that of Titanium.

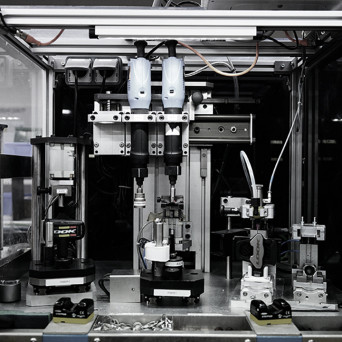

Sanding and Control

STEP 2

With 100% control over the entire production, 100% archiving of the initial rigidities plus traceability of material batches, machines and operators, LOOK does everything to ensure that its carbon quality control ensures your quality on the road.

Decoration and Varnish

STEP 3

In order to provide high-quality products, we pay extreme attention to the finish of the product. Decoration, paint and varnishing undergo individual and highly demanding controls

Aero Test

STEP 4

For us, it’s not just about talking. That’s why we give utmost importance to testing all prototypes in wind tunnel to scientifically guarantee the quality of our innovations.

#CARBONCORE